Silent Piling Press

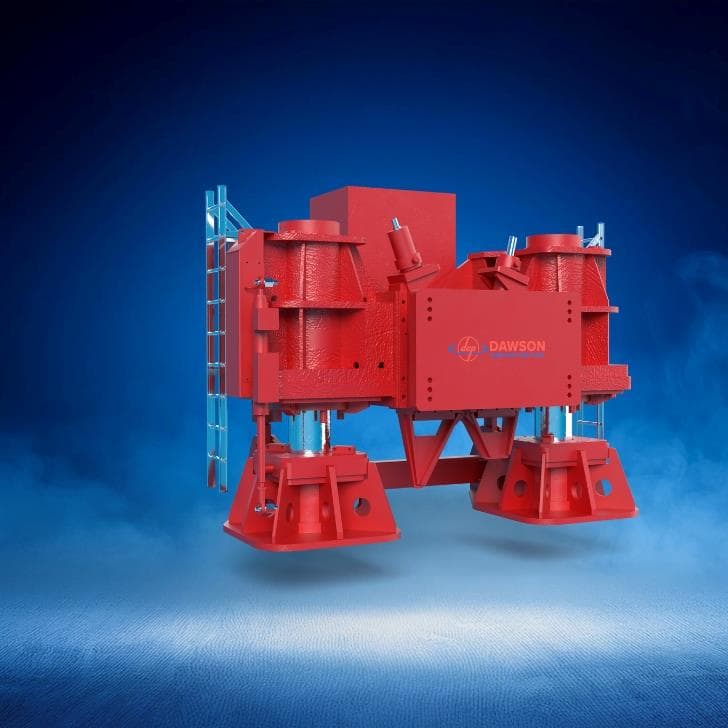

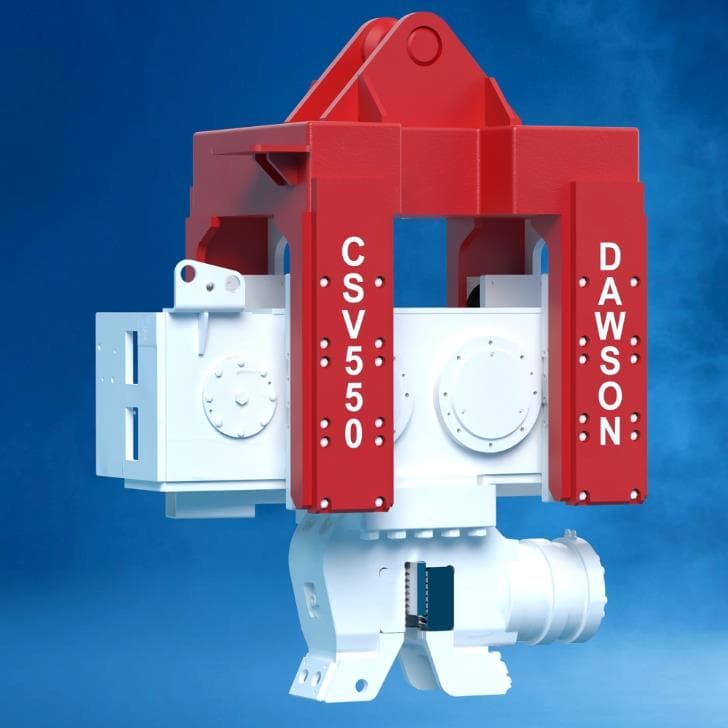

2-Cylinder, 3-Cylinder, 4-Cylinder

Dawson Silent Piling Pressing System – Powerful, Precise & Vibration-Free

Experience quiet, vibration-free pile installation and

extraction with the Dawson Silent Piling Pressing System—the ultimate solution

for efficient, high-quality steel sheet and foundation pile handling.

Engineered for speed, precision, and minimal environmental impact, this system

ensures a seamless, noise-reducing piling process while maintaining structural

integrity.

Key Advantages:

✔ Silent & Vibration-Free Operation – Ideal for urban, sensitive, and restricted environments.

✔ Powerful Pressing Force – Up to 200 tonnes for effective installation and extraction.

✔ High Productivity & Cost Efficiency – Fast cycle times boost project efficiency.

✔ Versatile Pile Handling – Supports Z, U & H-pile profiles in groups of 2 to 6.

✔ No Reaction Frame Needed – Unlike conventional presses, eliminating extra setup.

✔ Perfect Alignment, Minimal Friction – Rigid leader ensures high-quality, precise installations.

✔ Recyclable Foundation Solution – Sustainable and eco-friendly, reducing environmental impact.

✔ Maximized Development Footprint – Standard Z-piles can be installed close to property boundaries.

✔ Easy Pile Removal – Restores sites to their original greenfield condition.

Additional Benefits:

🚀 High-Capacity Foundation Piling – Supports interlocked box formations (4-6 piles) with SWL capacities up to 1,400 tonnes.

🌍 Eco-Friendly Process – No spoil removal, no ground heave, and fully recyclable piles.

⚡ Immediate Load Application – Pile capacity is measured during installation for instant usability.

🛠️ Adaptable & Efficient – Handles side loads, extends piles for piers/columns, and eliminates crane threading.

Upgrade your piling process with Dawson’s Silent Piling Pressing System—where power meets precision, without the noise or disruption.

| Specification | Units | 2-cylinder U & Z-piles | 3-cylinder U & Z-piles | 4-cylinder Z-piles | 4-cylinder U-piles |

|---|---|---|---|---|---|

| Pressing force per cylinder | kN | 2,078 | 2,078 | 2,078 | 2,078 |

| Extraction force per cylinder | kN | 2,078 | 2,078 | 2,078 | 2,078 |

| Maximum cylinder advance distance | mm | 600 | 600 | 600 | 600 |

| Cylinder advance rate | mm/min | 5,890 | 5,890 | 5,890 | 5,890 |

| Weight | kg | 7,000 | 11,500 | 13,000 | 13,000 |

| Required hydraulic pressure | bar | 350 | 350 | 350 | 350 |

| Minimum required hydraulic flow rate | L/min | 350 | 350 | 350 | 350 |

| Electrical supply | Volts/Amps | 24DC/10A | 24DC/10A | 24DC/15A | 24DC/15A |

| Specification | Units | 2-cylinder U & Z-piles | 3-cylinder U & Z-piles | 4-cylinder Z-piles | 4-cylinder U-piles |

|---|---|---|---|---|---|

| Pressing force per cylinder | ton | 233 | 233 | 233 | 233 |

| Extraction force per cylinder | ton | 233 | 233 | 233 | 233 |

| Maximum cylinder advance distance | in | 23.6 | 23.6 | 23.6 | 23.6 |

| Cylinder advance rate | in/min | 232 | 232 | 232 | 232 |

| Weight | lbs | 15,430 | 25,300 | 28,650 | 28,650 |

| Required hydraulic pressure | psi | 5,075 | 5,075 | 5,075 | 5,075 |

| Minimum required hydraulic flow rate | gpm | 93 | 93 | 93 | 93 |

| Electrical supply | Volts/Amps | 24DC/10A | 24DC/10A | 24DC/15A | 24DC/15A |

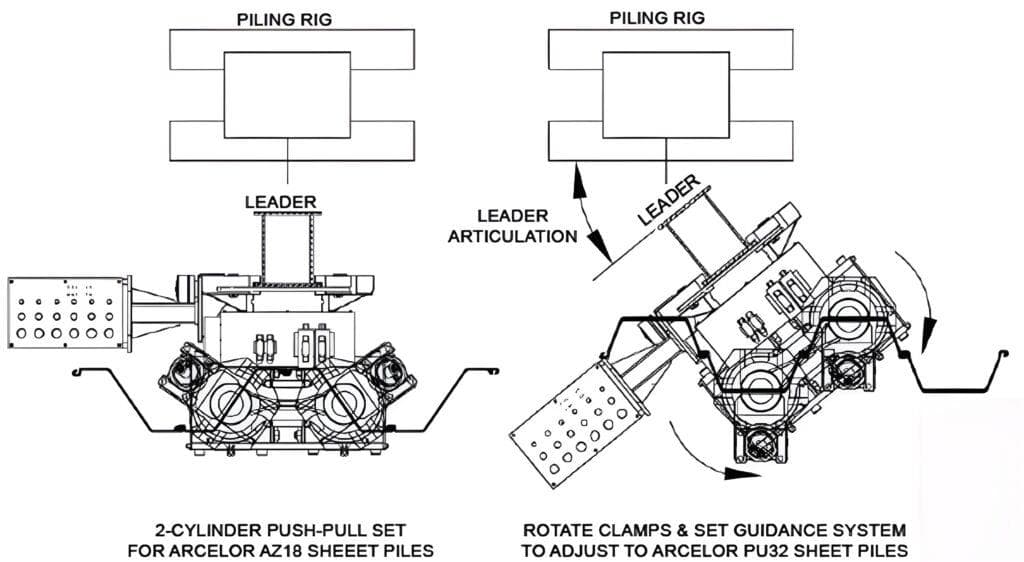

Leader Articulation

The leader should have the ability to articulate or pivot (in plan view). This is typical of any rig that has been engineered to undertake sheet-pile work – though alternative arrangements can be supplied. This feature offers two significant operational benefits:

- The entire piling process is faster, more economic and safer when the operator has the ability to see what he is doing. Lead articulation means the operator can position the leader for good visibility with minimum track movement.

- The 2-Cylinder Push-Pull unit can accomodate numerous pile profiles simply by articulating the lead and/or adjusting the rotational setting of the individual cylinder assemblies. The example below shows the same 2-Cylinder Push-Pull unit working with Arcelor AZ18 and PU32 steel sheet piles.

- The centres of the two Modular Hydraulic Cylinder Sub-Assemblies remains the same, but the Adjustable Guidance System is altered to correctly align the Clamp Assemblies with the clamping faces of each pile.